Master of Technology in Instrumentation Engineering

Online M.Tech in Instrumentation Engineering is a postgraduate program offered through online platforms that focuses on advanced concepts and techniques in the field of instrumentation and control systems. Instrumentation Engineering deals with the design, development, and maintenance of instruments and control systems used in various industries, including manufacturing, process control, automation, and robotics.

The online M.Tech program in Instrumentation Engineering is designed to provide working professionals and individuals with a flexible and convenient option to pursue higher education without compromising their career or personal commitments. Through the online platform, students can access course materials, lectures, and assignments, and interact with faculty and peers from anywhere at their own pace.

The curriculum of the online M.Tech in Instrumentation Engineering covers a wide range of subjects such as sensors and transducers, control systems, signal processing, measurement techniques, industrial automation, robotics, and more. Students gain in-depth knowledge of the latest advancements in instrumentation technology, emerging trends, and industry best practices.

The program combines theoretical knowledge with practical skills by incorporating laboratory exercises, simulations, and real-world case studies. Students are exposed to software tools and programming languages commonly used in the field of instrumentation engineering, enabling them to analyze, design, and optimize complex control systems.

The online M.Tech program also emphasizes research and innovation, encouraging students to undertake projects and contribute to the development of new technologies in the field. They are guided by experienced faculty members who provide mentorship and support throughout the program.

Upon completion of the online M.Tech in Instrumentation Engineering, graduates have numerous career opportunities in industries such as oil and gas, power generation, manufacturing, pharmaceuticals, automotive, aerospace, and more. They can work as instrumentation engineers, control system engineers, automation specialists, research scientists, consultants, or pursue academic and research positions.

Master of Technology in Instrumentation Engineering: Course Highlights

| Key Highlights | Description |

| Degree | Master of Technology (M.Tech) in Instrumentation Engineering |

| Mode of Education | Online, / Distance |

| Program Duration | Typically 2 years (varies based on the institution) |

| Eligibility Criteria | Bachelor’s degree in Engineering/Technology in a relevant field (Instrumentation/Electronics/Electrical) with a minimum percentage requirement |

| Curriculum | Subjects include sensors and transducers, control systems, signal processing, measurement techniques, industrial automation, robotics, and more. |

| Learning Platform | An online learning platform providing access to course materials, lectures, assignments, and discussion forums |

| Flexibility | Study at your own pace and convenience, suitable for working professionals and individuals with personal commitments |

| Faculty Support | Interaction with experienced faculty members for guidance, mentorship, and support |

| Practical Component | Incorporates laboratory exercises, simulations, and real-world case studies to develop practical skills |

| Research Opportunities | Emphasis on research and innovation with project work and opportunities to contribute to advancements in the field |

| Career Opportunities | Instrumentation engineer, control system engineer, automation specialist, research scientist, consultant, academic and research positions |

Why Pursue Online MTech in Instrumentation Engineering?

- Career Advancement: An M.Tech degree is highly valued in the engineering industry and can open up new career opportunities. It equips you with advanced knowledge, skills, and specialization in instrumentation engineering, making you a competitive candidate for higher-level positions, research roles, and leadership positions.

- Specialized Expertise: Instrumentation engineering is a specialized field that deals with the design, development, and maintenance of instruments and control systems. Pursuing an M.Tech allows you to delve deeper into advanced concepts and techniques specific to instrumentation engineering, enabling you to become an expert in the field.

- Industry Relevance: Instrumentation and control systems play a vital role in various industries, including manufacturing, energy, automation, aerospace, pharmaceuticals, and more. With an M.Tech in Instrumentation Engineering, you acquire skills that are directly applicable to these industries, making you a valuable asset in sectors that rely on precise measurement, control, and automation.

- Research and Innovation: Pursuing an M.Tech provides opportunities for research and innovation. You can undertake projects, collaborate with faculty members, and contribute to advancements in instrumentation technology. This can lead to the development of new solutions, technologies, and patents, expanding your knowledge and impact in the field.

- Personal and Professional Development: Pursuing higher education, such as an M.Tech, demonstrates a commitment to personal and professional growth. It enhances your analytical, problem-solving, and critical-thinking abilities. It also improves your communication and teamwork skills through collaboration with faculty and peers.

- The flexibility of Online Learning: Pursuing an M.Tech in Instrumentation Engineering online offers flexibility and convenience. Online programs allow you to study at your own pace and balance your education with work or personal commitments. You can access course materials, lectures, and assignments from anywhere, eliminating the need to relocate or commute to a physical campus.

- Networking Opportunities: Online M.Tech programs often provide opportunities for networking and collaboration with professionals in the field. Interacting with faculty members, industry experts, and fellow students can help you build a strong professional network, leading to potential job opportunities, mentorship, and collaborations.

- Salary Potential: An M.Tech degree generally commands higher salary prospects compared to a bachelor’s degree. With specialized knowledge and skills in instrumentation engineering, you can negotiate better compensation packages and enjoy enhanced earning potential.

Who Can Pursue MTech in Instrumentation Engineering?

- Accreditation: Ensure that the institution offering the online M.Tech program is accredited by a recognized accrediting agency. Accreditation ensures that the institution meets certain quality standards in terms of curriculum, faculty, facilities, and student support.

- Reputation: Research the reputation of the institution and its engineering department. Look for rankings, reviews, and feedback from current and former students. A well-established and respected institution is more likely to provide a high-quality education and have strong industry connections.

- Faculty Credentials and Expertise: Explore the qualifications, expertise, and research interests of the faculty members associated with the program. Experienced faculty members with industry experience and research publications can contribute significantly to your learning experience.

- Curriculum and Specializations: Review the curriculum and course offerings of the online M.Tech program. Ensure that it covers the key areas of instrumentation engineering and includes subjects relevant to your career goals. Look for any specializations or elective courses that align with your interests.

- Learning Platform and Technology: Evaluate the online learning platform used by the institution. Ensure that it provides a user-friendly interface, facilitates interactive learning, and offers access to course materials, lectures, assignments, and discussion forums. Check if the technology requirements are compatible with your devices and internet connectivity.

- Alumni Network and Industry Connections: Consider the institution’s alumni network and industry connections. An active alumni network and collaborations with industry partners can provide networking opportunities, internships, and potential job placements.

- Support Services: Assess the availability of support services for online students, including academic advising, technical support, library access, and career services. These services can contribute to a smooth learning experience and assist you in achieving your academic and career goals.

- Affordability and Financial Aid: Evaluate the tuition fees and any financial aid options available for the online M.Tech program. Consider your budget and explore scholarships, grants, or employer sponsorship opportunities.

M.Tech Instrumentation Engineering: Eligibility Criteria

- Academic Qualifications: Candidates are generally required to have a bachelor’s degree in Engineering/Technology in a relevant field such as Instrumentation Engineering, Electronics Engineering, Electrical Engineering, or a related discipline. The degree should be obtained from a recognized university or institution.

- Minimum Percentage Requirement: Many institutions have a minimum percentage requirement in the qualifying degree. It can vary but is often around 50% to 60% or a specified grade equivalent

- Entrance Exam: Some institutions may require candidates to appear for a relevant entrance examination. The examination may be at the national, state, or institutional level. Common entrance exams for M.Tech admissions in India include GATE (Graduate Aptitude Test in Engineering), PGCET (Post Graduate Common Entrance Test), or institution-specific entrance exams.

- Work Experience (if applicable): Some institutions may prefer or require candidates to have relevant work experience in the field of Instrumentation Engineering. Work experience requirements, if any, can vary from one institution to another.

- English Language Proficiency: Proficiency in the English language is typically required, especially for international students. Applicants may need to provide proof of English language proficiency through standardized tests such as TOEFL (Test of English as a Foreign Language) or IELTS (International English Language Testing System).

Online M.Tech Instrumentation Engineering: Admission Process

- Application: Begin by filling out the online application form provided by the institution offering the program. Make sure to provide accurate and complete information. The application form may require personal details, educational qualifications, work experience (if applicable), and other relevant information.

- Document Submission: After submitting the application form, you will usually be required to submit supporting documents.

- Selection Process: The institution will review your application along with the supporting documents.

- Acceptance and Fee Payment: Upon receiving the admission offer, you will need to confirm your acceptance by paying the admission fees within the specified deadline. The institution will provide information on accepted payment methods.

- Enrollment and Course Registration: Once you have accepted the admission offer and paid the fees, the institution will guide you through the enrollment process. You will be provided with login credentials and instructions on how to access the online learning platform. You can then proceed to register for courses.

Entrance Exam

| Entrance Exam | Description |

| GATE (Graduate Aptitude Test in Engineering) | A national-level entrance exam was conducted in India for admission to postgraduate engineering programs. |

| PGCET (Post Graduate Common Entrance Test) | A state-level entrance exam conducted by various states in India for admission to postgraduate programs. |

| TANCET (Tamil Nadu Common Entrance Test) | A state-level entrance exam conducted in Tamil Nadu, India, for admission to postgraduate programs. |

| AP PGECET (Andhra Pradesh Post Graduate Engineering Common Entrance Test) | A state-level entrance exam conducted in Andhra Pradesh, India, for admission to postgraduate programs. |

| TS PGECET (Telangana State Post Graduate Engineering Common Entrance Test) | A state-level entrance exam was conducted in Telangana, India, for admission to postgraduate programs. |

| KIITEE (KIIT Entrance Examination) | An entrance exam was conducted by the Kalinga Institute of Industrial Technology (KIIT) in India for admission. |

| BITS HD (BITS Higher Degree Entrance Exam) | An entrance exam was conducted by Birla Institute of Technology and Science (BITS) for admission to M.Tech programs. |

| VITMEE (VIT Master’s Entrance Examination) | An entrance exam was conducted by the Vellore Institute of Technology (VIT) in India for admission to postgraduate programs. |

How to Prepare for the Entrance Exam for M.Tech in Instrumentation Engineering

- Understand the Syllabus: Start by familiarizing yourself with the exam syllabus. Obtain the official syllabus or exam pattern provided by the conducting body or the institution offering the program. This will give you a clear understanding of the topics and subjects that will be covered in the exam.

- Create a Study Plan: Develop a comprehensive study plan that outlines the topics you need to cover and allocates time for each subject. Divide your study time effectively, giving more attention to areas where you feel less confident. Make sure to set realistic goals and follow the plan consistently.

- Gather Study Materials: Collect the necessary study materials, including textbooks, reference books, online resources, previous years’ question papers, and study guides specific to the entrance exam. Quality study materials can provide a solid foundation for your preparation and help you understand key concepts.

- Focus on Basics and Fundamentals: Build a strong foundation in the fundamentals of Instrumentation Engineering. Review core subjects such as control systems, sensors and transducers, electronic instrumentation, signal processing, measurement techniques, and industrial automation. Pay attention to fundamental mathematical concepts and numerical problem-solving techniques.

- Practice Previous Years Question Papers: Solve previous years’ question papers and sample papers to get an idea of the exam pattern, question types, and time management. This will help you understand the level of difficulty, identify important topics, and improve your problem-solving skills. Analyze your performance and identify areas where you need improvement.

- Mock Tests and Online Practice: Take mock tests and online practice quizzes specifically designed for the entrance exam. Mock tests simulate the actual exam environment and help you become familiar with the time constraints and exam format. They also provide an opportunity to assess your readiness and identify areas for improvement.

- Seek Clarification and Guidance: If you encounter any doubts or difficulties while preparing, seek clarification from teachers, subject matter experts, or online forums. Joining online communities or discussion groups related to the entrance exam can provide valuable insights and guidance from fellow aspirants.

- Time Management and Revision: Allocate sufficient time for revision. Review and consolidate the topics you have studied regularly. Create concise notes or flashcards to summarize important formulas, concepts, and key points. Practice time management techniques to improve your speed and accuracy during the exam.

- Stay Updated and Practice Regularly: Keep yourself updated with the latest developments and trends in Instrumentation Engineering. Follow relevant industry news, research publications, and advancements in the field. Regular practice and consistent effort are key to improving your knowledge and performance.

- Take Care of Yourself: Alongside your studies, ensure you maintain a healthy lifestyle. Get enough sleep, eat a balanced diet, and engage in regular physical exercise to keep your mind and body in optimal condition.

Required Skills for MTech Instrumentation Engineering

- Strong Analytical and Problem-Solving Skills: Instrumentation engineers often encounter complex problems that require analytical thinking and problem-solving abilities. Developing strong analytical skills enables you to break down problems, identify the underlying issues, and propose effective solutions.

- Solid Mathematical and Numerical Aptitude: Instrumentation Engineering involves mathematical modeling, data analysis, and numerical calculations. Proficiency in mathematical concepts such as calculus, differential equations, linear algebra, and probability theory is crucial for understanding and solving engineering problems.

- Technical Competence: A strong foundation in core engineering subjects such as control systems, sensors and transducers, signal processing, and electronics is essential. Being technically competent allows you to understand and work with instrumentation and control systems effectively.

- Programming and Software Skills: Proficiency in programming languages like C, C++, MATLAB, or Python is valuable in Instrumentation Engineering. These skills enable you to develop algorithms, simulate systems, and analyze data. Familiarity with software tools used in instrumentation and control, such as LabVIEW or PLC programming software, is also advantageous.

- Knowledge of Instrumentation and Control Systems: Understanding the principles, components, and working of instruments, sensors, and control systems is vital. This includes knowledge of measurement techniques, signal conditioning, data acquisition, feedback control, and industrial automation.

- Attention to Detail and Accuracy: Precision and attention to detail are crucial in Instrumentation Engineering to ensure accurate measurements, precise calculations, and reliable system performance. Developing meticulousness and an eye for detail enhances the quality and effectiveness of your work.

- Communication and Collaboration Skills: Strong communication skills, both verbal and written, are essential for presenting ideas, reports, and research findings. The ability to effectively communicate technical concepts to colleagues, clients, and stakeholders is valuable. Additionally, collaboration skills facilitate working in interdisciplinary teams, sharing knowledge, and engaging in effective problem-solving.

- Adaptability and Continuous Learning: Instrumentation Engineering is a rapidly evolving field with advancements in technology and techniques. Being adaptable and open to learning new concepts and technologies is crucial for staying updated and relevant. Embracing lifelong learning and being proactive in acquiring new knowledge and skills is important for professional growth.

- Critical Thinking and Innovation: Instrumentation engineers often face unique challenges that require critical thinking and innovative approaches. The ability to think creatively, evaluate alternatives, and propose novel solutions contributes to advancements in the field and improves the efficiency of instrumentation systems.

- Time Management and Organization: Online M.Tech programs require self-discipline, effective time management, and organizational skills. Balancing coursework, assignments, and personal commitments is essential to meet deadlines and complete the program successfully.

M.Tech Instrumentation Engineering: Syllabus

Semester I | Semester II |

| Advanced Mathematical Techniques | Advanced Control Theory |

| Linear Control Theory | Process control & Instrumentation |

| Modeling & Simulation of dynamic systems | Digital Control Systems |

| Transducer Technology | Control System Laboratory II |

| Control System Laboratory I | Instrumentation Laboratory II |

| Instrumentation Laboratory I | – |

| Detection & Estimation | – |

| Microwave circuits | – |

| Elective I | – |

| Elective II | – |

Semester III | Semester IV |

| Remote Sensing and Control | Project |

| Robotics | – |

| Reliability & Safety Engineering | – |

| Artificial Engineering | – |

Similar Studies Option

- Control Systems Engineering: Control Systems Engineering focuses on the design, analysis, and implementation of control systems in various applications. It involves studying feedback control theory, system modeling, and the design of controllers to regulate and optimize system behavior. This field is closely related to Instrumentation Engineering as both deal with control and automation technologies.

- Automation and Robotics Engineering: Automation and Robotics Engineering involve the design, development, and implementation of automated systems and robotic devices. This field encompasses areas such as industrial automation, robot programming, machine vision, and artificial intelligence. It shares common principles with Instrumentation Engineering in terms of control systems, sensors, and automation technologies.

- Mechatronics Engineering: Mechatronics Engineering is an interdisciplinary field that combines elements of mechanical engineering, electronics, computer science, and control systems. It focuses on the integration of mechanical systems with electronics and software to create intelligent and automated systems. Mechatronics Engineering shares common ground with Instrumentation Engineering, particularly in the areas of sensors, actuators, and control systems.

- Industrial Engineering: Industrial Engineering involves optimizing complex systems and processes to improve efficiency, productivity, and quality. It emphasizes the integration of people, machines, materials, and information to achieve optimal performance in industrial settings. Instrumentation Engineering skills, such as measurement techniques, data acquisition, and control systems, can be valuable in industrial engineering applications.

- Electronics and Communication Engineering: Electronics and Communication Engineering deals with the design, development, and maintenance of electronic devices, communication systems, and networks. It encompasses areas such as analog and digital electronics, telecommunications, signal processing, and embedded systems. Instrumentation Engineering shares common foundational knowledge with Electronics and Communication Engineering, particularly in electronic circuits, signal processing, and communication technologies.

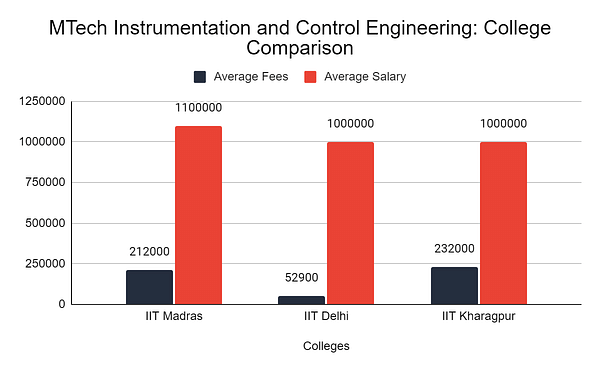

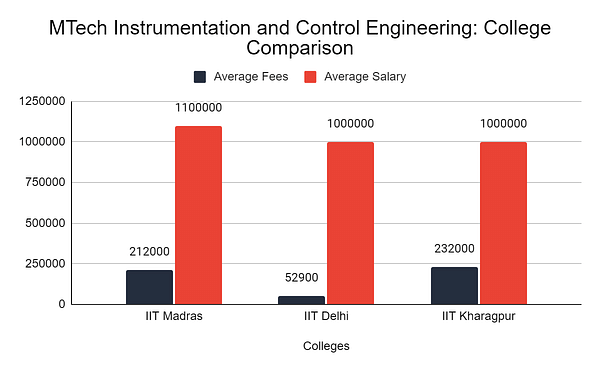

Top Online MTech Instrumentation Engineering Colleges in India

| Institution | Program Name |

| Sophia Online College | M.Tech in Instrumentation Engineering |

| Indian Institute of Technology Bombay (IIT Bombay) | M.Tech in Control and Automation, M.Tech in Systems and Control |

| Indian Institute of Technology Madras (IIT Madras) | M.Tech in Control and Instrumentation |

| Indian Institute of Technology Kanpur (IIT Kanpur) | M.Tech in Control and Automation |

| Indian Institute of Technology Kharagpur (IIT Kharagpur) | M.Tech in Control System Engineering, M.Tech in Instrumentation and Signal Processing |

| National Institute of Technology Trichy (NIT Trichy) | M.Tech in Industrial Automation and Robotics |

| National Institute of Technology Warangal (NIT Warangal) | M.Tech in Instrumentation and Control Engineering |

| Birla Institute of Technology and Science (BITS Pilani) | M.Tech in Instrumentation Engineering |

| Vellore Institute of Technology (VIT) | M.Tech in Electronics and Instrumentation Engineering |

| Manipal Institute of Technology (MIT Manipal) | M.Tech in Industrial Automation and Robotics |

Course Comparison

| Aspect | MTech in Instrumentation and Control Engineering | MTech in Electrical Engineering |

| Focus | Primarily focuses on the field of instrumentation, control systems, and automation technologies. | Primarily focuses on various aspects of electrical systems, power systems, and electrical devices. |

| Course Subjects | Control systems, sensors and transducers, signal processing, measurement techniques, industrial automation, robotics, process control, and instrumentation design. | Power systems, electrical machines, power electronics, electrical drives, renewable energy systems, high voltage engineering, and electrical system design. |

| Career Opportunities | Employment opportunities in industries related to automation, robotics, process control, manufacturing, power plants, oil and gas, and research and development. | Wide range of career opportunities in power generation and distribution companies, electrical equipment manufacturing companies, consulting firms, research organizations, and academia. |

| Job Roles | Control Systems Engineer, Instrumentation Engineer, Automation Engineer, Robotics Engineer, Process Control Engineer. | Power Systems Engineer, Electrical Design Engineer, Power Electronics Engineer, Electrical Project Manager, Renewable Energy Engineer. |

| Skillset Required | Strong understanding of control systems, sensors, data acquisition, signal processing, programming, and industrial automation. | Solid foundation in electrical systems, power distribution, electrical machines, power electronics, renewable energy systems, and problem-solving skills. |

| Research Areas | Advanced control systems, intelligent systems, robotics, machine learning applications in instrumentation, process optimization, and industrial automation. | Power system analysis, smart grids, renewable energy integration, power quality, power electronics applications, and energy management systems. |

| Industry Demand | Growing demand in industries adopting automation, process control, robotics, and industrial IoT technologies. | Sustained demand in power generation, distribution, renewable energy sectors, electrical equipment manufacturing, and infrastructure development. |

| Electives Available | Electives related to advanced control systems, robotics, artificial intelligence, digital signal processing, and optimization techniques. | Electives related to power system analysis, power electronics, energy management, smart grids, renewable energy systems, and electric vehicles. |

| Research vs. Industry Orientation | Balanced focus on both research-oriented and industry-oriented coursework and projects. | Can have both research and industry-oriented specializations, depending on the chosen electives and project work. |

Instrumentation Engineer: Career Option and Job Prospects

| Career Option | Job Description | Average Salary (INR) |

| Control Systems Engineer | Design, develop, and implement control systems for various applications and industries. | 6,00,000 – 10,00,000 |

| Instrumentation Engineer | Design, calibrate, and maintain instrumentation systems and devices for accurate measurements and control. | 5,00,000 – 8,00,000 |

| Automation Engineer | Develop and implement automated systems and processes for increased efficiency and productivity. | 6,00,000 – 10,00,000 |

| Robotics Engineer | Design and program robotic systems for industrial automation, research, and other applications. | 6,00,000 – 10,00,000 |

| Process Control Engineer | Monitor and optimize industrial processes using control systems to ensure safe and efficient operation. | 6,00,000 – 10,00,000 |

| Industrial Automation Engineer | Implement automation solutions for industries to enhance productivity and reduce human intervention. | 5,00,000 – 8,00,000 |

| Instrumentation Design Engineer | Design and develop instrumentation systems and components for specific applications. | 5,00,000 – 8,00,000 |

| Research and Development Engineer | Conduct research and development activities to innovate and improve instrumentation and control technologies. | 6,00,000 – 10,00,000 |

| Project Manager | Manage instrumentation and control projects, coordinate teams, and ensure successful project delivery. | 8,00,000 – 15,00,000 |

| Academia/Teaching | Pursue a career in academia, teaching and mentoring students in the field of Instrumentation Engineering. | Varies depending on the institution |

Instrumentation Engineering: Top Recruiting Companies

| Company |

| Larsen & Toubro (L&T) |

| Tata Consultancy Services (TCS) |

| Honeywell |

| ABB |

| Siemens |

| Emerson |

| Schneider Electric |

| Yokogawa |

| Bharat Heavy Electricals Limited (BHEL) |

| Indian Oil Corporation Limited (IOCL) |

| Reliance Industries Limited (RIL) |

| Hindustan Petroleum Corporation Limited (HPCL) |

| Oil and Natural Gas Corporation Limited (ONGC) |

| National Thermal Power Corporation (NTPC) |

| Bharat Electronics Limited (BEL) |

Future Scope of M.Tech Instrumentation Engineering

- Industrial Automation: With the ongoing trend of automation in industries, there is a growing need for professionals who can design, implement, and optimize automation systems. Instrumentation engineers play a crucial role in developing control systems, integrating sensors and actuators, and ensuring the smooth operation of automated processes.

- Robotics and AI: The integration of robotics and artificial intelligence (AI) is revolutionizing industries. Instrumentation engineers with knowledge of robotics, machine learning, and intelligent systems can contribute to the development of advanced robotic systems used in manufacturing, healthcare, defense, and other sectors.

- Internet of Things (IoT): The IoT is transforming the way devices and systems communicate and interact. Instrumentation engineers can leverage their expertise to design IoT-enabled sensors, develop data acquisition systems, and contribute to the development of smart and interconnected systems.

- Renewable Energy Systems: The focus on clean energy and sustainability has led to increased adoption of renewable energy sources. Instrumentation engineers can contribute to the design, monitoring, and control of renewable energy systems such as solar power plants, wind farms, and biomass facilities.

- Research and Development: There are ample opportunities for research and development in the field of Instrumentation Engineering. Advancements in control systems, signal processing, sensors, and automation technologies require continuous innovation and improvement. Pursuing research projects and collaborating with academia or industry can lead to advancements and new discoveries in the field.

- Consulting and Entrepreneurship: Instrumentation engineers with expertise in designing and implementing control systems, instrumentation, and automation technologies can explore opportunities in consulting firms or start their own businesses. They can provide specialized services and solutions to industries seeking to optimize their processes and improve efficiency.

- Academic and Teaching Careers: Pursuing a career in academia and teaching is another avenue for M.Tech graduates in Instrumentation Engineering. They can join universities, research institutes, or technical institutions as faculty members, imparting knowledge and contributing to the education of future engineers.

MTech in Instrumentation Engineering: FAQs

Q1: Can I pursue an online M.Tech in Instrumentation Engineering while working full-time?

A1: Yes, many universities and institutions offer online M.Tech programs in Instrumentation Engineering that are designed to be flexible and accommodate working professionals. You can pursue your studies at your own pace and manage your coursework alongside your job.

Q2: What are the eligibility criteria for an online M.Tech in Instrumentation Engineering?

A2: The eligibility criteria may vary between institutions, but generally, you need to have a relevant undergraduate degree in engineering (B.Tech or B.E.) in Instrumentation Engineering or a related field. Some institutions may also require a valid GATE (Graduate Aptitude Test in Engineering) score.

Q3: Are there any entrance exams for admission to online M.Tech in Instrumentation Engineering?

A3: Some institutions may require you to appear for entrance exams such as GATE or their own institution-specific entrance exams. However, the specific admission process and exam requirements vary across institutions, so it is advisable to check the respective institution’s website for detailed information.

Q4: What is the duration of the online M.Tech in Instrumentation Engineering program?

A4: The duration of the online M.Tech program in Instrumentation Engineering is typically two years, divided into semesters or trimesters. However, the actual program duration may vary between institutions and can depend on factors such as the curriculum structure and the mode of study (full-time or part-time).

Q5: What are the job prospects after completing an online M.Tech in Instrumentation Engineering?

A5: With an M.Tech in Instrumentation Engineering, you can pursue career opportunities in industries such as automation, robotics, process control, manufacturing, power plants, oil and gas, and research and development. Job roles may include Control Systems Engineer, Instrumentation Engineer, Automation Engineer, Robotics Engineer, Process Control Engineer, and more.

Q6: Can I pursue a Ph.D. after completing an online M.Tech in Instrumentation Engineering?

A6: Yes, an M.Tech in Instrumentation Engineering provides a solid foundation for further academic pursuits, including a Ph.D. You can explore research opportunities in specialized areas within the field or related interdisciplinary fields.